Insulation Design in the Power Module

Insulation Design in the Power Module

1. Electric Shock Hazard

The current flowing through the human body will cause the physiological reaction of the human body, and the intensity of the reaction depends on the magnitude, duration, and path through the human body of the current, etc. Generally, only a current of 0.5mA is needed to have an impact on a healthy human body, and may cause indirect harm. Larger currents may cause direct harm to the human body, such as burns or fibrillation of the ventricles.

Generally speaking, under dry conditions, a voltage of less than 40V peak or 60V DC can usually be regarded as a non-hazardous voltage. However, the bare parts that must be touched during use or need to be operated by hand should be connected to the protective ground or properly disposed of.

In order to prevent the human body (operator or maintenance personnel) from being shocked, it is necessary to comply with relevant industry safety design standards in the design of the switching power supply, such as IEC60950, national standard G4943, etc.; in these standards, different positions of the switching power supply are insulated requirements to ensure the safety of operators.

2. Insulation category

2-1: Functional insulation (Functional Insulation): The purpose of functional insulation is only to maintain the normal operation of the product, and it does not have any safety function. This type of insulation is usually used between two conductors in the same line, that is, parts where there is no requirement for safe separation. For example, the green oil on the PWB and the plastic case of the electrolytic capacitor are functional insulation.

2-2: Basic Insulation (Basic Insulation): The purpose of basic insulation is to provide a basic protection against electric shock to avoid the risk of electric shock, but this type of insulation can only guarantee safety under normal conditions, but cannot guarantee transients Safety in the presence of voltage, in other words, when a transient voltage occurs, there is a possibility that the basic insulation will collapse.

2-3: Supplementary Insulation (Supplementary Insulation): In addition to the basic insulation, additional insulation is provided to provide another layer of insulation function when the basic insulation fails. In general, the requirements for supplementary insulation are the same as for basic insulation, so the roles between the two are interchangeable. For example, if a cable has two layers of insulation, we can say that the inner layer is basic insulation and the outer layer is supplementary insulation, and vice versa.

We must pay attention to one thing, that is, the supplementary insulation must be established only when the basic insulation exists.

2-4: Double Insulation (Double Insulation): This refers to the insulation that includes both basic insulation and supplementary insulation. As long as it is used in the right place, this insulation can provide sufficient safety protection without the risk of electric shock.

2-5: Reinforced insulation (Reinforce Insulation): It provides the same degree of insulation as double insulation, but the difference from double insulation is that it is not easy to be divided into two parts: basic insulation and supplementary insulation. It may be an integrally formed isolation objects, or insulation composed of many spacers.

2-6: The protection against electric shock of Class I tools not only relies on basic insulation, but also includes a protective zero connection or grounding measure, so that the exposed conductive parts cannot become charged when the basic insulation is damaged. Such appliances should be connected to sockets equipped with effective grounding terminals for use, or grounding wires should be added to the shell separately, that is, electrical products that must have grounding devices.

2-7: The protection against electric shock of class II tools not only relies on basic insulation, but also includes additional double insulation or reinforced insulation,

(Protective neutral or ground connection not provided or independent of device condition, case marked "back".)

(Type II tools are further divided into Type II tools with insulating material shells and Type II tools with metal material shells.)

(The "back" mark refers to Class II appliances with double insulation or reinforced insulation structure, and the shell does not need to be grounded.)

2-8: The protection against electric shock of class III tools relies on the power supply of safety extra-low voltage, and the voltage higher than the safety extra-low voltage shall not be generated in the tool.

3. Electrical clearance and creepage distance

3-1: Electric clearance: refers to the shortest space distance measured between two conductive parts or between a conductive part and the interface of the equipment. The measurement of the distance does not limit the method used. For example, if a product uses insulating material as the casing, the openings or gaps in the casing should be considered as conductors. If there is a layer of aluminum foil on it, it is still necessary to keep a certain distance from the internal dangerous parts, because these places are within easy reach of users.

3-2: Creepage distance: refers to the shortest distance between two conductive parts or between a conductive part and the equipment protection interface measured along the insulating surface. Generally speaking, if the pollution degree is not 1, the creepage distance is usually greater than the clearance.

The electrical clearance and creepage distance are related to the working voltage, pollution level, altitude, insulating material, etc. The actual design electrical clearance and creepage distance requirements on the PCB need to be calculated according to the standard requirements based on specific details such as insulation level requirements, working voltage, pollution level, altitude, and insulating materials.

3-3: Altitude: According to Bassett's law, the breakdown voltage of a harmonious electric field is proportional to the product of the air pressure and the distance between the two poles. When the distance between the two poles is constant, the smaller the air pressure, the lower the breakdown voltage . The air pressure is inversely proportional to the altitude, so the altitude is one of the important factors affecting the spatial distance.

General safety standards set the maximum altitude of the product to 2000m, and a correction factor needs to be considered if it exceeds 2000m, see the table below:

Both IEC60950-1 and UL60950-1 are required at an altitude of 2000m. If the altitude of 5000m is to be met, then all clearance distance requirements need to be multiplied by a factor of 1.48. For example, the original 2000m requires clearance and creepage distances of 4mm and 5mm, then 4*1.48=6mm is required for use at an altitude of 5000m, and the creepage distance requirement must be equal to or greater than the corresponding electrical clearance requirement, so in this case the electrical clearance and creepage distance requirements are both 6mm. Many products that apply for CCC have a warning mark on the nameplate "only suitable for use below 2000m altitude", because they cannot meet the electrical clearance requirements at an altitude of 5000m.

4. Pollution level:

If there is pollution in the space between the two conductors, it will also affect the degree of insulation. General standards divide pollution into four levels

Pollution degree 1: No pollutants or only dry and non-conductive pollutants are present. This level of pollution can be met by using a closed enclosure or by coating the surface of the circuit board

Pollution degree 2: Refers to pollution with occasional conductive pollutants, such as condensation of water vapor. Generally, there is only non-conductive pollution, but occasional short-term conductive pollution caused by condensation must be taken into account.

Pollution degree 3: There is conductive pollution, or non-conductive pollution becomes conductive due to expected condensation.

Pollution degree 4: Cause persistent conductive pollution, such as pollution caused by conductive dust or rain and snow. Unless otherwise specified in the relevant product standards, industrial electrical appliances are generally selected for use in an environment with a pollution level of 3, and household and similar electrical appliances are generally selected for an environment with a pollution level of 2.

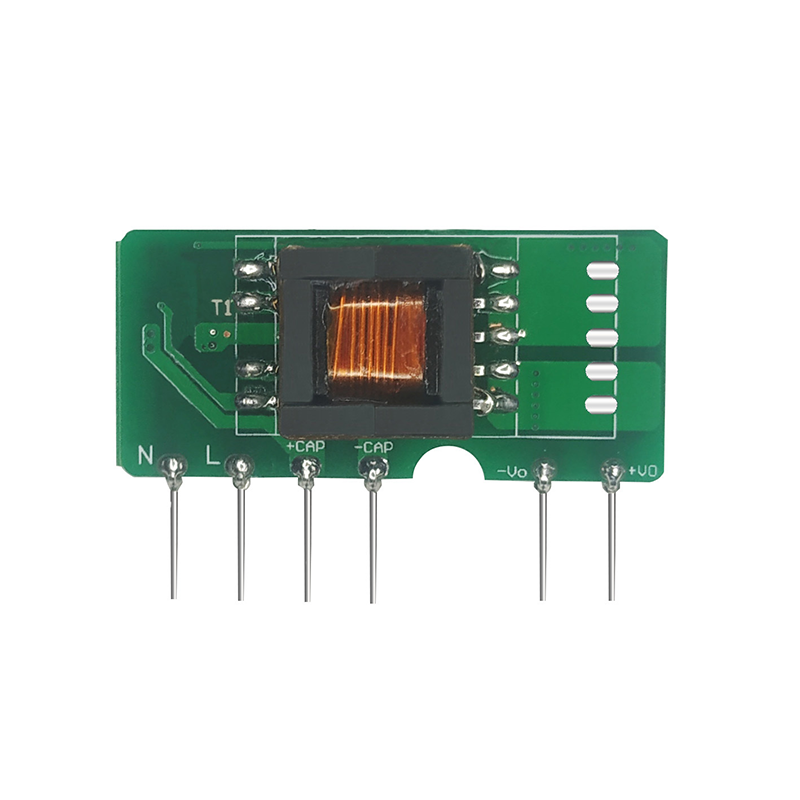

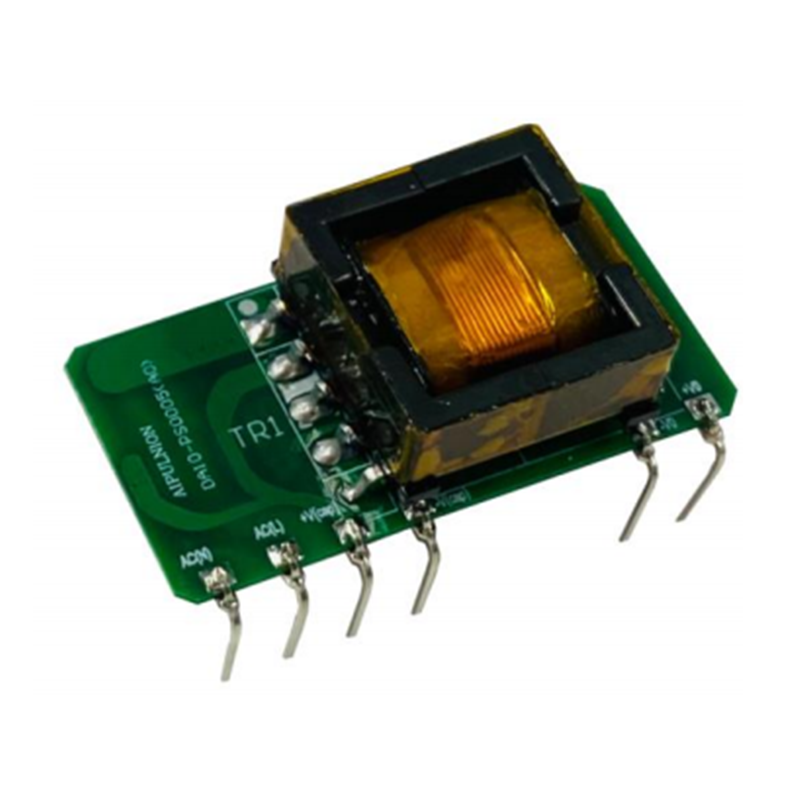

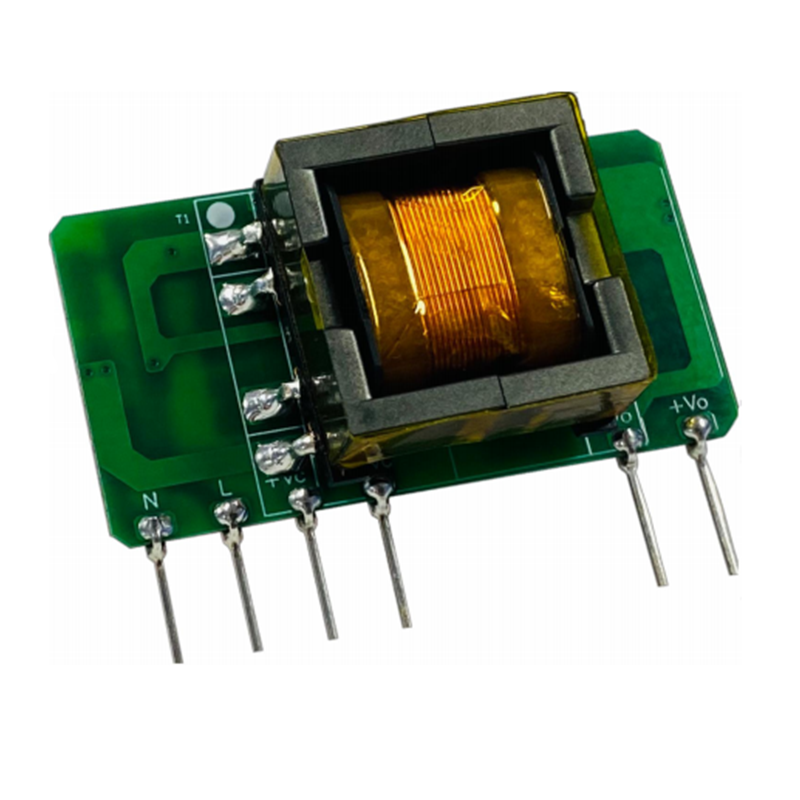

5. Working voltage test of high frequency transformer

Connect the input N line to the output GND, use the rated highest voltage for the input, load normally, use the oscilloscope DC coupling to measure the initial interval (such as transformer 1-7, 1-8, 2-7, 2-8, 3-7 ,3-8,4-7,4-8) Peak value and RMS value, this project test is more dangerous. The Peak value determines the electrical clearance, and the RMS value determines the creepage distance.

The optocoupler should also test the working voltage, test four times, 1-3, 1-4, 2-3, 2-4

The circuit test method diagram is as follows

6. Calculation and confirmation of electrical clearance and creepage distance

6-1: Confirmation of electrical clearance

For example, the requirements for the primary circuit and the electrical clearance between the primary circuit and the secondary circuit are determined according to the EN/IEC60950 standard. First test the working peak voltage of the transformer and calculate it according to Table2K and Table2L in the standard.

The following will explain how to calculate the minimum space distance according to the reinforced insulation requirements listed above. Refer to Table2K and Table2L to further understand the space distance requirements of the power module. The calculation standard is as follows.

6-1-1: According to 2.10.3.2, when the working voltage (Peak) of the transformer of the power module exceeds the voltage of the AC power supply, two steps can be taken to determine the minimum electrical clearance.

Step 1: Refer to Table 2K for the minimum electrical clearances required for insulation between the primary circuit and the secondary circuit of the primary circuit.

For example, when the operating voltage (Peak) of the power module transformer is 420V, it can be obtained from Table2K.

F functional insulation distance: 1.5mm

The distance between B/S basic insulation and additional insulation function: 2.0mm

R reinforced insulation distance: 4.0mm

6-1-2: According to the regulations of EN/IEC60950, when the working voltage of the transformer of the power module does not exceed 420V, the functional insulation is 1.5mm, the basic and additional insulation is 2mm, and the reinforced insulation is 4mm. If the working voltage exceeds 420Vpeak, then the Add up the values in Table2K and Table2L, since the working voltage exceeds 420Vpeak, it is necessary to calculate the distance according to step 2.

Step 2: Check the additional clearance required for insulation when the primary circuit operating voltage exceeds the rated AC power supply voltage in Table 2L.

For example, when the operating voltage of the power module transformer is far beyond 420Vpeak, that is, the measured value is 890Vpeak, you must find the 933Vpeak column of the 2500V column from Table2L, and the corresponding minimum electrical clearance is as follows.

The extra distance of F functional insulation is: 0.7mm

The additional distance between B/S basic insulation and additional insulation function is: 0.7mm

The additional distance for R reinforced insulation is: 1.4mm

6-1-3: The minimum electrical clearance is finally obtained:

Functional insulation (1.5mm+0.7mm)=2.3mm Basic insulation (2.0mm+0.7mm)=2.7mm

Reinforced insulation (4.0mm+1.4mm) = 5.4mm

In Table2K and Table2L standards, capital letter F stands for functional insulation, B stands for basic insulation, S stands for supplementary insulation, and R stands for reinforced insulation

6-2: Creepage distance confirmation

6-2-1: Examples

The input voltage of the power module is: 100V~240Vac

According to the actual measurement, the working voltage of the transformer of the power module is 365Vrms.

Pollution level: according to 2 levels

Material category: according to IIIa or IIIb

6-2-2: How to calculate the creepage distance required for basic insulation

Since the measured effective value of the input voltage of the working voltage is 365V, there is no such value in 2L in the above chart, so it needs to be calculated.

A: First, get the required creepage distance of 300Vrms from the above chart 2L = 3.2mm

B: The creepage distance required to get 400Vrms = 4.0mm

6-2-3: Final creepage distance calculation

The distance to be increased: (4mm-3.2mm)/(400-300)X(365V-300V)=0.52mm

3.2mm+0.52mm=3.75mm

If you need to meet reinforced insulation: (take the creepage distance required by basic insulation) X2 times,

That is, 3.75mmX2=7.44mm, the minimum creepage distance required for reinforced insulation=7.44mm

7. Examples

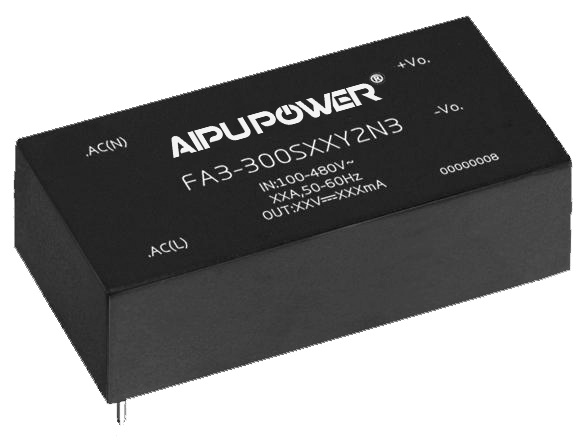

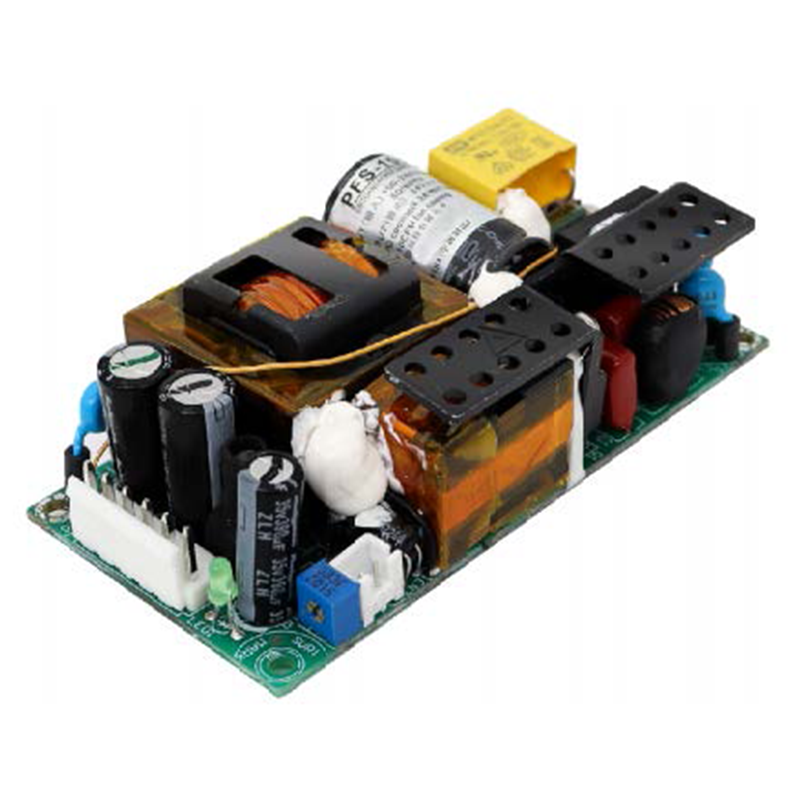

The figure below is a schematic diagram of the key components of a typical AC-DC switching power supply, mainly including the AC input part, the rectified high-voltage DC part, the DCDC conversion part, the secondary side circuit that the human body may come into contact with, and the protection ground, etc. The following takes this figure as an example to briefly introduce the calculation of the electrical clearance and creepage distance between different parts in the actual design of the switching power supply.

For each position in the circuit to the ground, that is, the AC input L\N to the ground, the high-voltage DC to the ground after rectification, the primary side to the ground, the secondary side to the ground, etc., all need to use basic insulation; for the internal components of a DC-DC line , since there is no risk of electric shock, it is only necessary to use functional insulation to ensure the normal operation of the circuit and reduce the risk of breakdown and ignition; and for the primary circuit to the secondary circuit, such as B\C to E in the figure, reinforced insulation must be used. To prevent people from being shocked by the dangerous primary circuit when they come into contact with the secondary circuit. The insulation level requirements of the components at each position in the figure and the maximum effective value and peak voltage between different positions are shown in the table below.

According to the table lookup, the minimum requirements for electrical clearances and safety distances between components at different positions in the schematic diagram are shown in the table below.