Detailed Explanation of the Three Major Protection Circuits Surge Protection

For switching power supplies, safety and reliability have always been regarded as one of the important performances. Under the condition that the electrical technical indicators of switching power supplies meet the normal use requirements of electronic equipment, they must also meet the requirements of external or internal circuit or load circuit failures. It can work safely and reliably even under conditions. For this reason, a variety of protection measures must be taken. After analyzing the characteristics of the protection circuit, we hope to overcome the existing shortcomings and design a safer and more reliable protection circuit.

1. Analysis of surge current circuit

Surge current is caused by a sudden change in voltage. For example, when an electronic device is first applied with voltage, the initial inrush current caused by the charging of a large-capacity power supply capacitor - the power-on surge current; another example is the direct lightning strike or induction lightning along the power supply. The transient current lightning surge current is generated by the sudden voltage of the line entering the switching power supply. The rise time of the surge current is very fast, the duration is very short, and the destructive effect is very large. In order to prevent or reduce the damage of the surge current, set up to suppress the surge current Or transfer the surge current to the ground wire to protect the switching power supply from damage by surge current.

1) Start current limiting protection

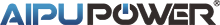

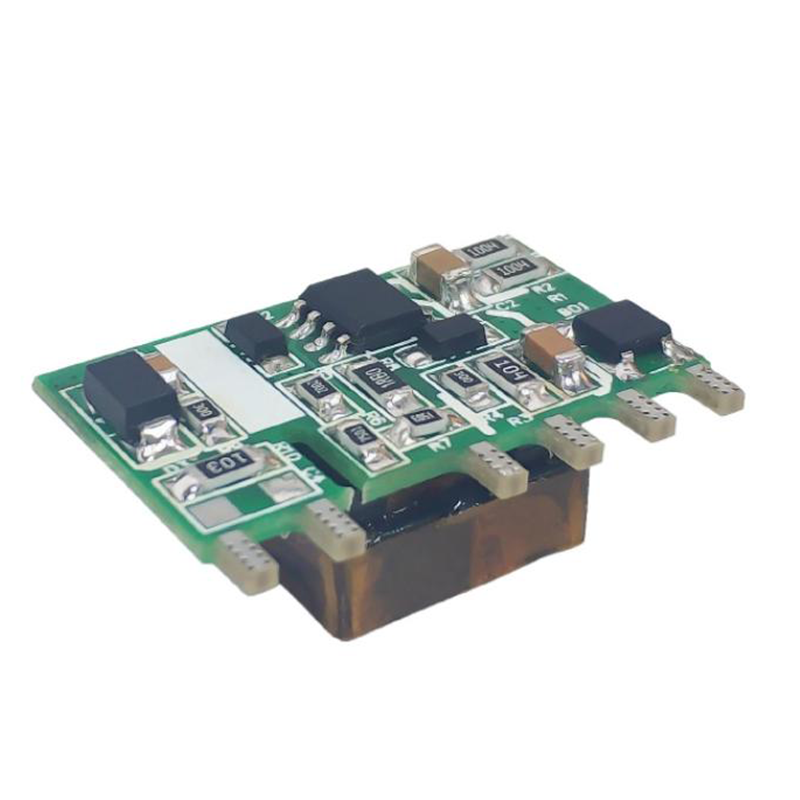

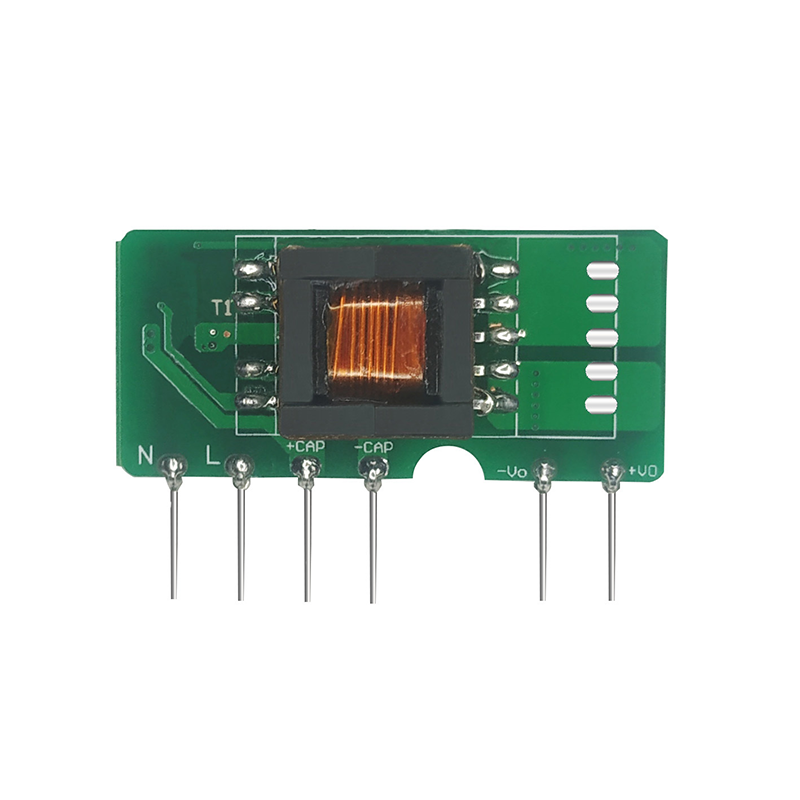

The primary rectifier circuit of the switching power supply has large-capacity filter capacitors. The rectifier charges these large capacitors at the moment of startup, causing the instantaneous current of the rectifier to exceed the rated value. In order to reduce the startup current limit (inrush current), switching power supplies are usually equipped with Anti-impact circuit. As shown in the circuit in Figure 1, at the moment of power-on, the voltage of windings 3 and 4 of the switching power supply transformer is 0V, VD5 is cut off, the voltage between the G and K poles of thyristor VD6 is 0V, and VD6 is cut off. Charging current path: AC220V→VD1 - 4 positive electrode→large capacitor C1→ground→R2→VD1- 4 negative electrode. Since R2 blocks large current (usually set to 3. 3Ω), it can effectively limit the power-on surge current.

After the switching power supply works normally, the induced voltage is generated on windings 1 and 2 of the switching power supply transformer, charging C2 (the charging time constant is approximately equal to R3×C2), causing VD6 to conduct, and the rectified current no longer passes through R2, but through VD6 The A and K poles return to the negative pole of the rectifier bridge VD1-4. That is to say, in normal working conditions, VD6 short-circuit R2 to prevent R2 from generating power consumption. R2 only works at the moment of power-on.

Using thyristors for starting current limiting protection is safe and reliable, but the circuit is more complicated. From the perspective of circuit cost and circuit simplicity, using temperature-controlled resistors for starting current limiting protection is economical, simple, safer and more reliable, as shown in Figure 3.

2) Lightning surge current protection

When a power grid transmission line is struck by lightning or induced lightning, the induced sudden voltage in the transmission line will generate a surge current. In order to prevent lightning surge voltage and current impact, one or several varistors are often connected in parallel to the input end of the power supply to release lightning. The impact of surge current. Figure 2 The circuit uses a varistor to prevent lightning surge current. The varistor Rv shows high impedance (approximately open circuit) under normal conditions. When the power grid transmission line encounters a lightning strike or induced lightning, the varistor Rv When both ends of RV exceed its starting voltage in an instant, it will immediately change from high impedance to low impedance (approximate short circuit), causing the lightning surge current to be released. At the same time, the AC fuse F will melt, preventing the transmission line from being damaged by lightning strikes or induced lightning. Purpose of electronic equipment.

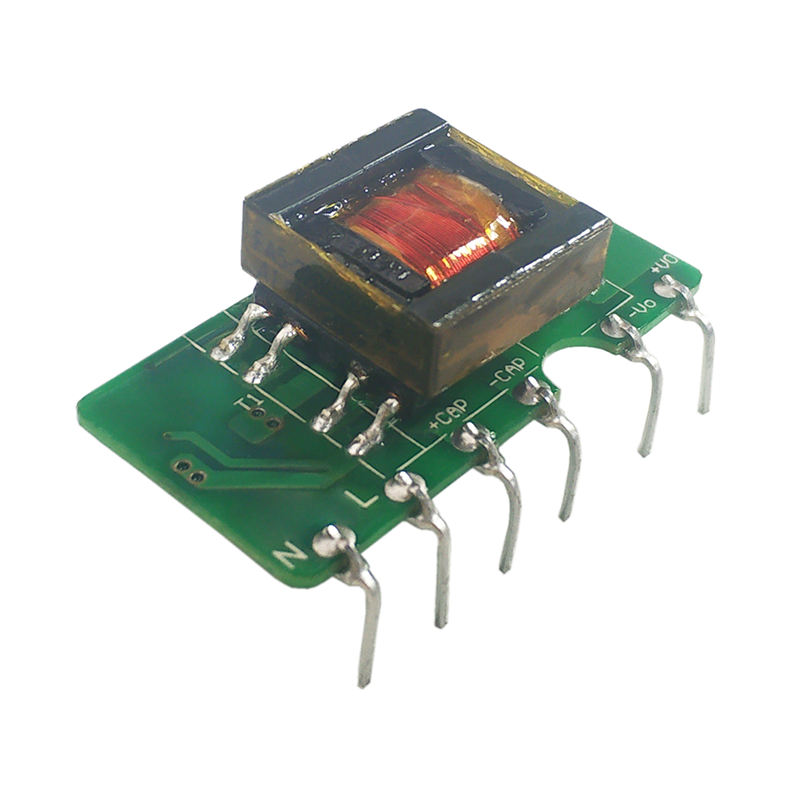

3) Actual circuit analysis and simulation testing

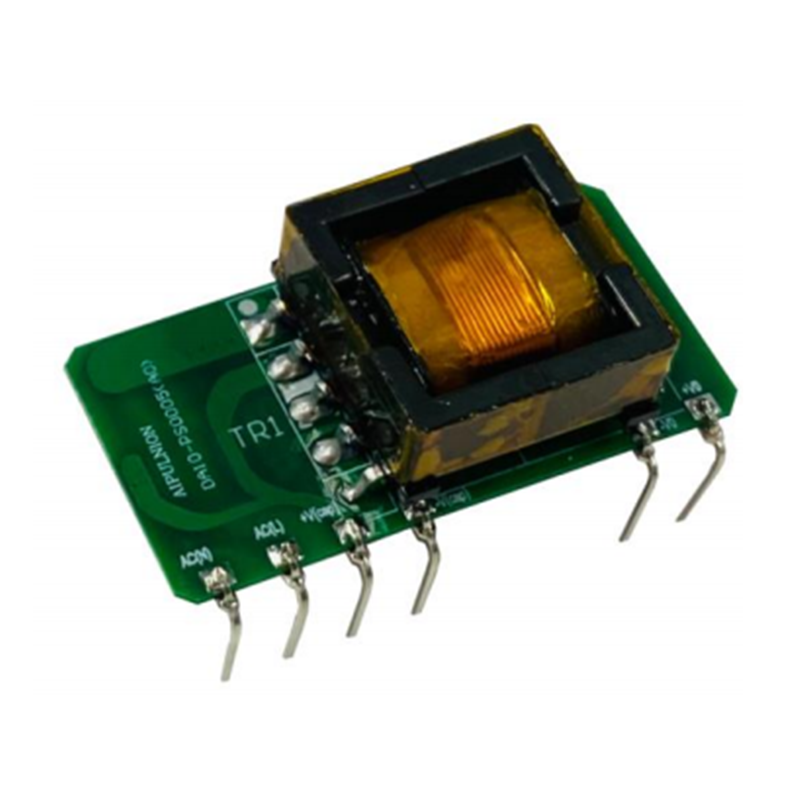

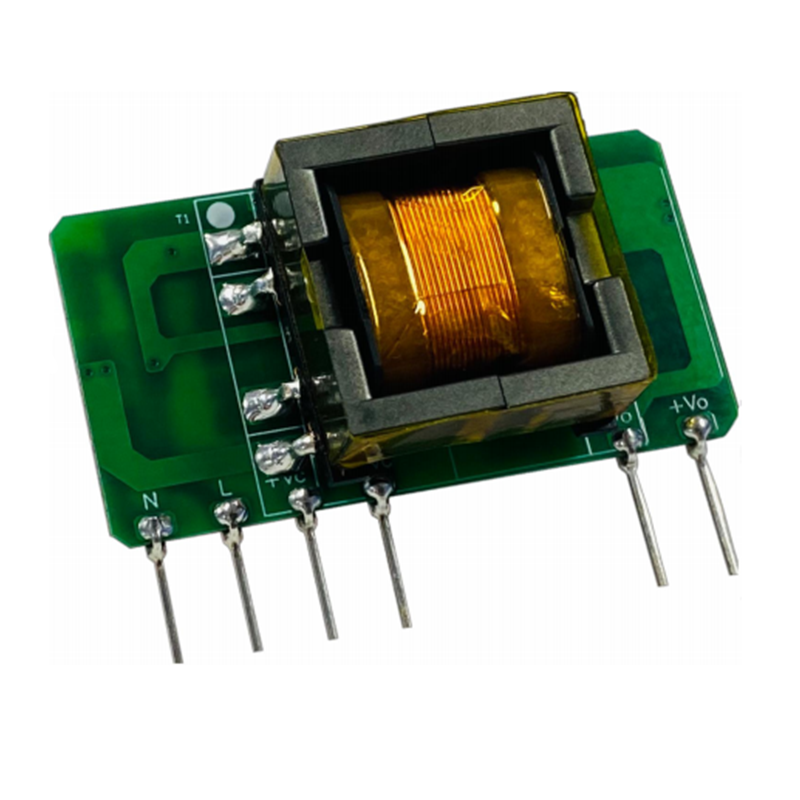

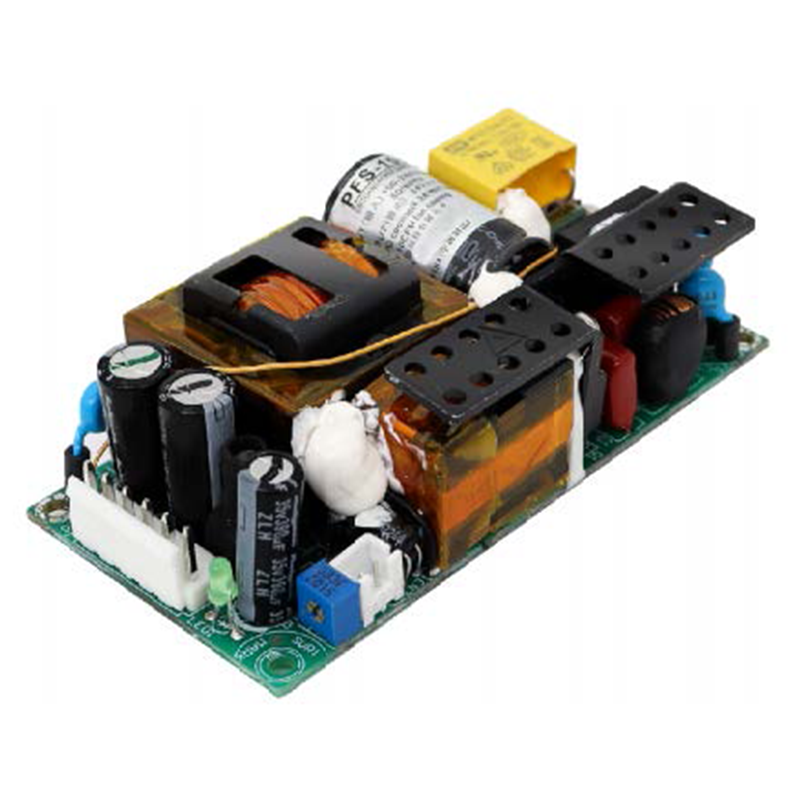

The circuit in Figure 3 is a typical partial circuit of an actual switching power supply.

Lightning protection unit: When there is a lightning strike and high voltage is generated and introduced into the power supply through the power grid, the circuit composed of Rv1, Rv2, Rv3, F1, F2, F3 and FDG provides protection. When the voltage applied to both ends of the varistor exceeds its working voltage , its resistance value decreases, causing the high-voltage energy to be consumed by the varistor. If the current is too large, F1, F2, and F3 will burn out the subsequent protection circuit.

Anti-boot surge unit: When the power is turned on, C needs to be charged. Due to the large instantaneous current, all its energy is consumed on the temperature-controlled resistor Rt. Since the characteristic of Rt is that the resistance decreases exponentially as the temperature rises (Rt is negative). Temperature coefficient element), the resistance value of Rt decreases (shows low impedance) after the instantaneous temperature rise. At this time, it consumes very little energy and the subsequent circuit can work normally. The temperature control resistor Rt changes from high impedance to low impedance, which is effective ground to prevent surge current.

Simulation experiment: Using a lightning surge current generator to simulate the protection circuit, the experimental test waveforms before and after the protection circuit is added are shown in Figure 4 and the startup surge current test waveform is shown in Figure 5. The simulation experiment shows that the common feature of the surge current is that the action time is short (several to tens of nanoseconds), the surge current is large (the lightning surge current can reach tens to thousands of amperes, and the startup surge current exceeds the operating current by more than dozens of times). After adding a protection circuit, the peak is cut off.

2. Analysis of over-current protection circuit

As we all know, when the power output exceeds the rated load or is short-circuited or the control circuit loses control capabilities, it will cause the electronic equipment to not work properly or cause damage to the electronic equipment. The over-current protection circuit includes the circuit-breaking method and the oscillator frequency modulation method.

1) Circuit breaking method over-current protection

The most economical and simple way to prevent over-current in a circuit is to use a fuse. Fuse blowing protection is divided into two categories: AC fuse and DC fuse. When an accident occurs to the load current, the current exceeds the fusing value of the fuse (the fusing coefficient is generally 1.1 ~ 1.5), the fuse blows to achieve over-current protection. However, at the moment of power-on, due to the charging of the large capacitor, a large surge current will be generated. This surge current is generally several times the normal input current. , it is easy for the fuse to blow and misjudgment to occur, which is its main flaw.

2) Oscillator frequency modulation method over-current protection

The so-called frequency modulation method is to generate a control signal through the detection and comparison amplifier circuit to change the oscillation frequency of the oscillator, thereby reducing the load voltage, thereby achieving the purpose of reducing the load current. Usually the over-current protection setting value is 110% ~ 130% of the rated current. %, can be automatically restored.

Under the coupling of the transformer, if there is an overload or short circuit at the output end, the primary current will increase quickly, and the voltage VRS on the detection resistor RS (manganese copper wire) will increase. In Figure 6 (A ) This voltage VRS exceeds the B-E turn-on voltage of V2, and V2 turns on. Since the collector of V2 is connected to the control end of the oscillation circuit, the oscillation of the oscillation circuit slows down or stops. In Figure 6 (B) VRS voltage The comparator outputs a control signal to the oscillation circuit to adjust the oscillation frequency, reduce the output voltage, reduce the load current, and achieve the purpose of protection. The over-current protection accuracy of Figure 6(B) and Figure 6(A) is higher, because (B) The circuit is designed with error comparison and error amplification circuits.

Figure 7 shows the constant current over-current protection circuit. In the circuit, R1 and R2 divide VR. The divided voltage VR2 on resistor R2= VR[ R2/ ( R1+ R2) ] load current I0, measured on resistor RS. The voltage VS= I0RS, the voltage VS is compared with VR2, if VS> VR2, A outputs a control signal, which changes the pulse signal frequency, causes the output voltage to drop, and the output current I0 decreases.

Figure 8 is a common photocoupler drive over-current protection circuit. Its working principle: When the output current is too large, the voltage at both ends of RS rises, the IC2② pin voltage is higher than the ③ pin reference voltage, IC2 outputs high voltage, and V1 is turned on. The photoelectric effect occurs in the photocoupler IC1, which causes the oscillation frequency of the oscillation circuit to change, thereby changing the width (or frequency) of the pulse signal that controls the switching tube, causing the output voltage to decrease, thereby achieving the purpose of output overload current limiting.

3) There are deficiencies

The detection resistor RS is always connected in series in the circuit. If the value of the detection resistor RS is small, the circuit protection response speed is not fast and the accuracy is not high. If the value of the detection resistor RS is too large, the power consumption will increase significantly. The detection resistor RS There is reactive power loss that reduces the efficiency of the switching power supply. In order to reduce the reactive power loss of the detection resistor RS, circuits such as detection signal amplification will be used to improve the response speed and accuracy of the protection circuit.

3. Analysis of over-voltage protection circuit

Over-voltage in the switching power supply circuit is divided into external over-voltage and internal over-voltage. Both of them will cause the electronic equipment to work abnormally or burn out the components of the electronic equipment. The external over-voltage of the power supply is mainly due to the wrong connection to the 380 V voltage; the internal over-voltage mainly comes from the switch. The power supply circuit abnormality or component damage (loss of voltage stabilization control) causes the output voltage to be too high. The most common over-voltage protection circuits include the circuit-breaking method and the switching tube cut-off method.

1) Circuit breaking method over-voltage protection

The external over-voltage mainly comes from the high voltage of the industrial frequency grid, such as the wrong connection to the voltage of 380 V. As shown in Figure 9, it is a circuit that uses relay J to turn off the circuit for protection. When the AC power supply is normal, the voltage of the voltage regulator tube VS is The current is very small, IRR < VbeQ, so the transistor V is cut off, and the relay J is in a normally closed (conducting) state. When the AC power supply is higher than the normal state value for some reason, the current through the voltage regulator VS is very large, IRR > VbeQ , causing the transistor V (saturated) to conduct, and the relay J to operate, cutting off the input circuit, thereby protecting the switching power supply circuit and the load circuit. When the AC power supply returns to normal, the transistor V is cut off, and the relay J is in a normally closed (conducting) state. The advantage is that it can automatically restore power supply, but the disadvantage is that it has poor stability and the size of relay J is large.

2) Switch tube cut-off method over-voltage protection

The circuit of the switching power supply itself is abnormal or the components are damaged (loss of voltage stabilization control), causing the output voltage to be too high. Figure 10 shows an over-voltage protection circuit driven by a thyristor. Under normal voltage output conditions, the third winding of T803 The positive voltage at the upper end and the negative voltage at the lower end cannot cause VD to break down and conduct after being divided by R1 and R2. The thyristor V2 is also cut off, and the protection circuit does not operate. For some reason, the switching tube V1 loses voltage stabilization control, and the output voltage rises abnormally. High, the voltage of the third winding of high-frequency transformer T will exceed the breakdown voltage value of VD after being divided by R1 and R2, causing VD to break down and causing the thyristor V2 to trigger and conduct. After the thyristor V2 triggers, the capacitor C The upper end is connected to the ground, and the switch tube V1 is turned off quickly. After the voltage of the third winding of the high-frequency transformer T is rectified, the output of the voltage stabilizing circuit can weaken the oscillation control signal, further speeding up the cutoff of the switch tube V1. After the protection circuit is activated, due to the rectification and filtering The resulting DC voltage supplies power to the A pole of the thyristor V2 through R3, so V2 will continue to be turned on until the fault is removed and the machine is turned on again, at which point V2 will be turned off.

Figure 11 shows an over-voltage protection circuit driven by a photocoupler. Among them, the photocoupler IC1 plays two roles in the switching power supply. One is to implement a solid-state relay; the other is to isolate the input and output.

When the output voltage exceeds the normal value, driven by the error comparison amplifier IC2, the internal light-emitting diode of the photocoupler IC1 emits light, which in turn causes the internal phototransistor of the photocoupler IC1 to saturate and conduct, so the pulse current of the switch tube V is passed by the phototransistor. Short circuit, so the switch tube V is cut off quickly. After the protection circuit is activated, since the A pole of the auxiliary power supply DC voltage thyristor is powered, the thyristor will continue to conduct, and the phototransistor will also continue to be saturated and conductive until it is turned on again.

3) There are deficiencies

Since the switch tube is turned off, there is no output voltage. But when the input is connected incorrectly and a voltage of 380 V is introduced, the voltage applied to the filter capacitor, switch tube and other components is still 380 V. If the withstand voltage of these components is not enough, they will be damaged.

4. Actual circuit analysis

Figure 12 shows an actual switching power supply circuit. The 220 V alternating current is rectified and filtered to obtain a DC voltage of about 300 V, which is then added to the collector of V3 (high-power switch tube) through the 5 and 1 terminal windings of T3. L22 and L23 It can sustain the impact of the pulse current on the V3 electrode, and C23 and C24 can absorb the spike pulse of the V3 collector to prevent V3 breakdown damage. The windings at terminals 9 and 7 of T3 are positive feedback windings, and their feedback potential is coupled to V3 through R26 and C19. base, causing V3 to produce self-oscillation with an oscillation frequency of 30-60 kHz. VD39 provides a discharge circuit for the positive feedback coupling capacitor C19, and at the same time limits the reverse voltage of the b-e pole of V3 during the cut-off period to 0.7 V, to prevent b-e breakdown of V3.

V20 is a constant current drive tube. The potential of the windings at terminals 8 and 7 of T3 is rectified by VD20 and filtered by the C21 capacitor to establish a DC voltage of about 8 V. This voltage supplies power to the collector of V20 through R22. During the saturation period of the switching tube V3, T3 The potential at terminal 9 passes through R23 to conduct V20, so V20 provides a constant current drive current for V3, the size of which is determined by the resistance of R22. The constant current drive expands the AC input voltage range of the switching power supply to 90-270 V.

V21 has two functions. The first is over-voltage protection. When the voltage across C21 rises from the normal value of 8 V to 10 V, VD44 breaks down and turns on, causing V21 to turn on. The base excitation current of V3 is driven by the ce of V21. The pole is short-circuited, causing the switch V3 to be in a cut-off state and protected. The second function is to delay the conduction of V3. During the cut-off period of V3, the positive potential of terminal 8 and the negative potential of terminal 7 of T3 charge C33 through VD43. When V3 flips from the cut-off state to the saturation state, the charging voltage of C33 will maintain V21 to conduct for a period of time. During this period, V21 shunts the excitation current of the base of V3, which is to delay the conduction of V3. After a period of time, the collector voltage of V3 has dropped to a low point to reduce the power loss caused by the instant when V3 flips from cut-off to saturation state.

V38 is an under-voltage protection control tube. First, terminal 7 of T3 is at positive potential and terminal 9 is at negative potential. It is rectified by VD24 to establish a DC voltage of about -10 V on C26. This -10 V voltage is added to V38 through R69 and R67. In addition, the 300V voltage is also added to the base of V38 through R68. When the input AC voltage is lower than 110 V, that is to say, the DC voltage obtained after rectification and filtering decreases from 300 V to below 150V. At this time, the base of V38 The electrode potential also decreases, so V38 is turned on, which then causes V24 and V22 to turn on. The base excitation current of V3 is bypassed by V22, causing the switch tube V3 to be in a cut-off state for protection.

V25 is the over-current protection control tube, R39 is the over-current detection resistor of the switch tube V3, the over-current voltage drop on R39 is added to the base of V25 through R33, causing V25 to turn on, causing V22 to turn on, so the switch tube V3 is turned on due to the over-current. The flow is in a cut-off state.

Summary

Protection circuits are essential components in electronic devices to ensure the safety and reliability of the circuits. They are designed to detect abnormal conditions and take necessary actions to prevent damage or hazards. Here are three major protection circuits commonly used:

Over-current Protection Circuit: The over-current protection circuit is used to detect whether the current in the circuit exceeds a predefined safe value. Once the current exceeds the set value, the protection circuit immediately cuts off the circuit to prevent excessive current that can cause damage or fire hazards. This circuit is widely used in power supplies, motor control systems, and electrical appliances.

Over-voltage Protection Circuit: The over-voltage protection circuit is responsible for monitoring the voltage levels in a circuit. It detects if the voltage exceeds the safe operating range and takes appropriate actions to protect the circuit. The over-voltage protection circuit is crucial in safeguarding sensitive electronic components from voltage spikes or surges, which can lead to component failure or even device damage. It is commonly used in power supplies, telecommunications equipment, and automotive electronics.

Over-temperature Protection Circuit: The over-temperature protection circuit is designed to prevent overheating of electronic devices or circuits. It continuously monitors the temperature and triggers protective measures if the temperature exceeds the safe operating limit. The protective measures can include reducing power consumption, activating cooling mechanisms, or shutting down the device to prevent thermal damage. Over-temperature protection circuits are commonly found in computer systems, motor drives, and industrial equipment.

These three major protection circuits play a crucial role in ensuring the safety and reliability of electronic devices. They provide a safeguard against excessive current, voltage, and temperature, which can lead to equipment failure, fire hazards, or even personal injury. Implementing these protection circuits is essential in various industries to protect both the devices and the users.

The Significance of Protection Circuits

Protection circuits play a crucial role in ensuring the safety and reliability of electronic devices. They are designed to detect abnormal conditions and take necessary actions to prevent damage or hazards. Protection circuits are of utmost significance in the field of electronics. They provide safety, enhance reliability, protect equipment, offer cost savings, and ensure compliance with regulations. These circuits are vital components that contribute to the overall performance and longevity of electronic devices, making them an indispensable aspect of modern technology.